HRB වානේ තීරු, එනම්, Hot-rolled Ribbed Bar, hot-rolled ribbed bars, ඊනියා ribbed steel bar යන්නෙන් අදහස් කරන්නේ කොන්ක්රීට් සමඟ occlusal බලය වැඩි කිරීම සඳහා උණුසුම් පෙරළීමේ ක්රියාවලියෙන් විකෘති වූ වානේ තීරුවේ මතුපිටයි. මතුපිට රිබ්ඩ් වානේ තීරුව, සර්පිලාකාර තීරුව, හෙරින්ග්බෝන් බාර්, ක්රෙසන්ට් බාර්, ආදිය.

Rebar යනු උණුසුම් රෝල් කරන ලද රිබ්ඩ් වානේ බාර් සඳහා පොදු නමකි.සාමාන්ය උණුසුම්-රෝල් කරන ලද වානේ තීරුවේ ශ්රේණිය HRB සහ ශ්රේණියේ අවම අස්වැන්න ලක්ෂ්යයෙන් සමන්විත වේ.H, R සහ B යනු පිළිවෙළින් Hotrolled, Ribbed සහ Bars යන වචන තුනේ මුල් අකුරු වේ.

උණුසුම් රෝල් කරන ලද රිබ්ඩ් වානේ තීරුව ශ්රේණි තුනකට බෙදා ඇත: HRB335 (පැරණි ශ්රේණිය 20MnSi), තුන්වන ශ්රේණිය HRB400 (පැරණි ශ්රේණිය 20MnSiV, 20MnSiNb, 20Mnti) සහ හතරවන ශ්රේණිය HRB500.

| සම්මත | BS4449-2005,GB1449.2-2007,JIS G3112-2004, ASTM A615-A615M-04a, කොරියානු ප්රමිතිKS D 3504, AustralasianStandard AS/NZS 4671 |

| ශ්රේණියේ | BS4449, Gr460B,Gr500B, GB1449.2, HRB335, HRB400, HRB500, HRB400E, HRB500E, ASTM A615, GR40/GR60/GR75, JIS G390, SD ප්රමිතිKS D 3504 SD400 SD500 SD600, AustralasianStandard GR500N |

| ප්රමාණය | 6mm, 8mm, 10mm, 12mm, 13mm, 14mm, 16mm, 20mm, 22mm, 25mm, 30mm, 32mm, 40mm, 50mm, ආදිය. |

| දිග | 6-12m හෝ පාරිභෝගිකයාගේ අවශ්යතාවය අනුව හෝ දඟරයේ |

| අයදුම්පත | නිවාස, පාලම්, මාර්ග වැනි සිවිල් ඉංජිනේරු ඉදිකිරීම් |

| භාරදීම | සාමාන්යයෙන් තැන්පතු ලැබීමෙන් දින 3-10 කට පසුව හෝ පෙනීමේදී L/C |

| පැකේජය | මිටියක්, සම්මත මුහුදු සුදුසු පැකේජයක් හෝ පාරිභෝගික අවශ්යතා වලින් අසුරා ඇත |

සාමාන්යයෙන් රසායනික සංයුතිය, නිෂ්පාදන ක්රියාවලිය, රෝල් කිරීමේ හැඩය, සැපයුම් ආකෘතිය, විෂ්කම්භය ප්රමාණය සහ ව්යුහයේ භාවිතය අනුව වර්ගීකරණය කරන ලද රිබාර් වර්ග බොහොමයක් තිබේ:

1. විෂ්කම්භය අනුව

වානේ කම්බි (විෂ්කම්භය 3 ~ 5mm), තුනී වානේ තීරුව (විෂ්කම්භය 6 ~ 10mm), ඝන වානේ තීරුව (විෂ්කම්භය 22mm ට වැඩි).

2. යාන්ත්රික ලක්ෂණ අනුව

I පන්තියේ rebar (300/420);II පන්තියේ rebar (335/455);III පන්තිය රිබාර් (400/540) සහ IV පන්තිය (500/630)

3. නිෂ්පාදන ක්රියාවලිය අනුව

Hot-rolled, Cold-rolled, Cold-drawn Steel Bars, මෙන්ම IV ශ්රේණියේ වානේ තීරු වලින් සාදන ලද තාප පිරියම් කරන ලද වානේ බාර්, කලින් තිබූ ඒවාට වඩා වැඩි ශක්තියක් ඇත.

Rebar සැකසුම් සාමාන්යයෙන් ක්රියාවලි හතරක් හරහා සිදු වේ:

rebar මලකඩ ඉවත් කිරීම➜ rebar straightening➜ rebar කැපීම ➜ rebar පිහිටුවීම.

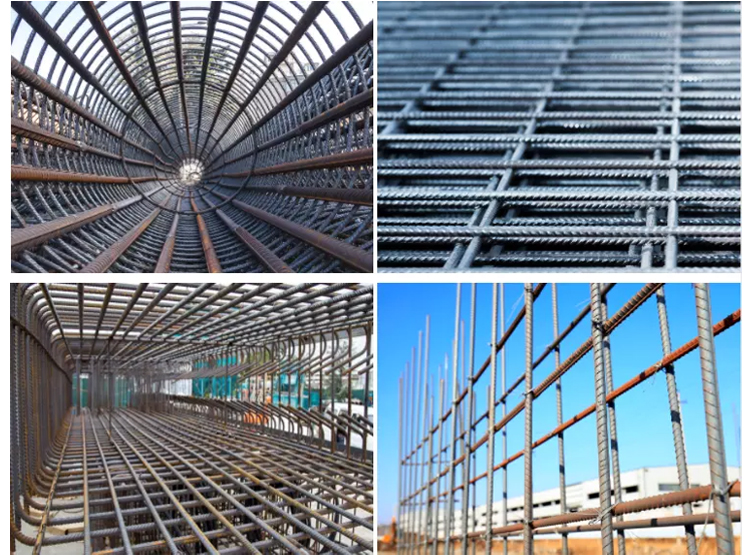

වර්තමානයේ, ශක්තිමත් කරන ලද කොන්ක්රීට් සිවිල්, කාර්මික සහ උස් ගොඩනැගිලිවල භාවිතා වේ.ඒවා තීරණය කරන ප්රධාන ද්රව්ය වේ

ගොඩනැගිල්ලේ දරණ ධාරිතාව.ශක්තිමත් කරන ලද කොන්ක්රීට් වෙනුවට ආදේශ කළ හැකි කොන්ක්රීට් වර්ගයක් දැනට නොමැත.එය බොහෝ විට භාවිතා වේ

අද පවතින ඉදිකිරීම් කටයුතු වලින්.විශේෂයෙන්ම, ශක්තිමත් කරන ලද කොන්ක්රීට් අවශ්ය වන විශාල ව්යාපෘතිවල එහි වාසි ප්රවර්ධනය කරයි

ඉහළ දරණ ධාරිතාව.උස් ගොඩනැගිලි, කාර්මික ගොඩනැගිලි, ගුවන් තොටුපළ, පාලම්, මාර්ග, ආදිය ශක්තිමත් කොන්ක්රීට් භාවිතා කරයි.

ප්ර: ඔබ නිෂ්පාදකයෙක්ද?

A: ඔව්, අපි Steel Rebar නිෂ්පාදකයෙක්, අපට චීනයේ Shandong හි පිහිටි කර්මාන්ත ශාලාවක් ඇත.විකෘති වානේ තීරු නිෂ්පාදනය සහ අපනයනය කිරීමේ ප්රමුඛ බලයක් අපට ඇත.ඔබ සොයන දේ අපි බවට අපි පොරොන්දු වෙමු.

ප්ර: අපට ඔබේ කර්මාන්ත ශාලාවට යා හැකිද?

A: ඔබගේ කාලසටහන ලැබුණු පසු අපි ඔබව සාදරයෙන් පිළිගනිමු.

Q: ඔබට තත්ත්ව පාලනයක් තිබේද?

A: ඔව්, අපට BV, SGS තුන්වන පරීක්ෂණය පිළිගත හැකිය.

ප්ර: ඔබට නැව්ගත කිරීම සංවිධානය කළ හැකිද?

A: නිසැකවම, බොහෝ නැව් සමාගමකින් හොඳම මිලක් ලබා ගත හැකි සහ වෘත්තීය සේවාවක් ලබා දිය හැකි ස්ථිර භාණ්ඩ ප්රවාහනය කරන්නෙකු අප සතුව ඇත.

ප්ර: ඔබේ භාරදීමේ කාලය කොපමණද?

A: සාමාන්යයෙන් භාණ්ඩ තොගයේ තිබේ නම් එය දින 7-14 කි.හෝ භාණ්ඩ තොගයේ නොමැති නම් එය දින 25-35 වේ, එය ප්රමාණය අනුව වේ.

Q: අපට පිරිනැමීම ලබා ගත හැක්කේ කෙසේද?

A:කරුණාකර ද්රව්ය, ප්රමාණය, හැඩය, යනාදී නිෂ්පාදනයේ පිරිවිතර ඉදිරිපත් කරන්න. එබැවින් අපට හොඳම දීමනාව ලබා දිය හැකිය.

ප්ර: අපට සාම්පල කිහිපයක් ලබා ගත හැකිද? කිසියම් ගාස්තුවක් තිබේද?

A:ඔව්, ඔබට අපගේ තොගයේ ඇති සාම්පල ලබා ගත හැක. සැබෑ සාම්පල සඳහා නොමිලේ, නමුත් පාරිභෝගිකයින්ට භාණ්ඩ ප්රවාහන ගාස්තු ගෙවිය යුතුය.

ප්ර: ඔබ අපගේ ව්යාපාරය දිගුකාලීන සහ යහපත් සබඳතාවක් ඇති කර ගන්නේ කෙසේද?

A: 1. අපි අපගේ ගනුදෙනුකරුවන්ගේ ප්රතිලාභ සහතික කිරීම සඳහා හොඳ තත්ත්වයේ සහ තරඟකාරී මිලක් තබා ගනිමු.

2. අපි සෑම පාරිභෝගිකයෙකුටම අපගේ මිතුරෙකු ලෙස ගෞරව කරන අතර ඔවුන් කොතැනක සිට පැමිණියද අපි අවංකව ව්යාපාර කරන අතර ඔවුන් සමඟ මිතුරු වන්නෙමු.